In the last few years, 3D printing has been touted as the next cool thing, with promises of it revolutionizing industries. While the focus has mostly been on manufacturing, the truth is that 3D printing will touch on almost every part of business, even reaching into space.

So what is 3D printing and why should businesses care?

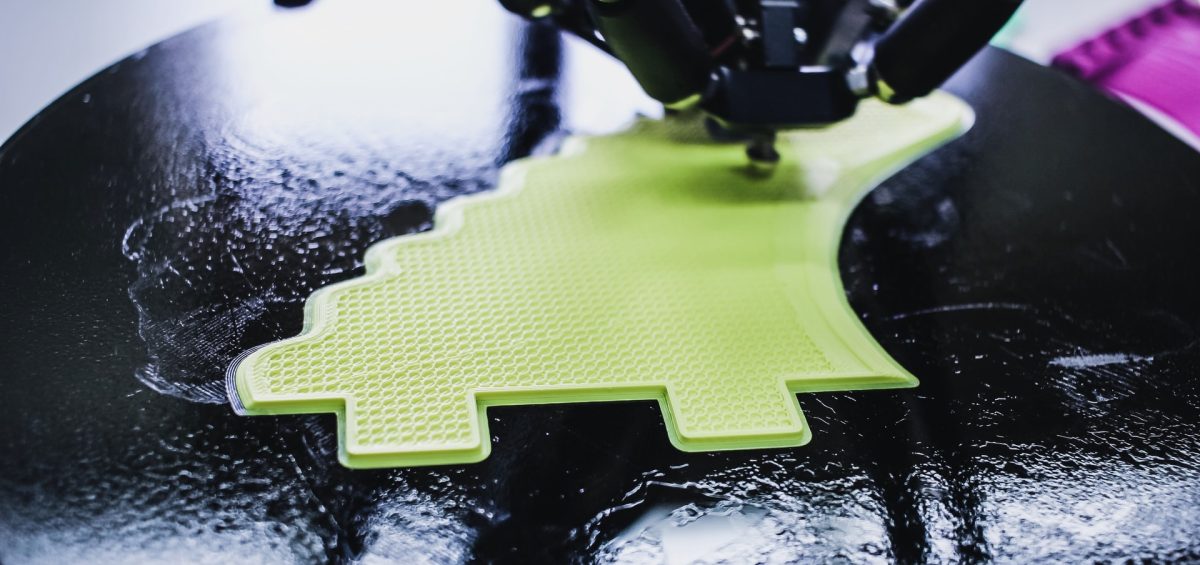

Also known as additive manufacturing, 3D printing is the process of creating objects from a digital model by joining and fusing material layer by layer. Unlike conventional manufacturing – sometimes called subtractive manufacturing – where the required materials are cut and processed with the extra material being thrown away, 3D printing has no waste.

Already, major companies are using 3D printing to round out production – GE, Boeing, Invisalign, Toyota, and even NASA are creating durable and safe products that are being used every day. Once seen as a niche technology, 3D printing is now a viable alternative to the traditional manufacturing process.

The biggest benefits are:

- Ultra-fast prototypes

- Reach more markets, more quickly

- Mass customization

- Reduced cost of manufacturing and overhead

- Manufacturing decentralized

- Revolutionize the supply chain process and speed

- More resource-efficient with almost zero waste

Entrepreneurs. For entrepreneurs and start-ups, creating prototypes can be cost-prohibitive, often in the hundreds of thousands of dollars. But with 3D printing the same prototype can start from as little as a few thousand dollars, opening the possibilities for more ingenuity and creativity, not to mention speed to market.

The Supply Chain. The experts agree that 3D printing will significantly change the supply chain. Consider the money that can be saved by no longer having to ship parts or patterns across the world. Imagine a jig – now custom made for pennies – that is designed in Italy but no longer needs to be shipped to Vietnam for manufacturing. Instead, the design can be downloaded from the cloud and 3D printed locally without the headache of customs, paperwork, shipping, and logistics.

Automotive Manufacturing. Motor vehicles and parts manufacturing is a huge business with manufacturers are looking for every opportunity to find efficiencies and reduce overhead. It should therefore be no great surprise that the automobile industry has shown the most, early interest in the technology, primarily due to its heavy reliance on parts. Toyota, for instance, requires an average of 30,000 individual parts for a single car. Being able to simplify and speed up the production of those parts, with less waste, would have a dramatic impact on cost and speed to market.

Construction. Skeptics of large-scale 3D printing should consider that the world’s first 3D printed neighborhood is currently being built in Mexico, replacing existing, poorly built structures. The developers hope to build 50 new houses twice as fast as regular construction, using a 33-foot printer that lays down a concrete mix, building the walls one layer at a time.

Medical. 3D printing is currently being used to customize prosthetics for patients, but it can also be deployed in a wide variety of other medical items – tissues, organs, surgical models, and tools. The technology is already being used to customize instruments for complex surgeries, as well as 3D models of patients’ internal systems before surgical procedures, so doctors can have a clearer picture of any challenges they might face.

Space. NASA has a 3D printer on the International Space Station so astronauts can build custom tools and components instead of having to send them from Earth. The agency is assessing the viability of this kind of solution for operations further afield like on the lunar surface or on Mars where a regular cargo supply is not possible. For long-duration missions, 3D printing could reduce logistics and the amount of mass needed to be put in flight.

Preparing For 3D Printing

If 3D printing is the right next step for your business, what should happen next? First, consider your customers’ needs, your offerings, and how 3D technology might fill any gaps, make the company more efficient, and speed time to market. For instance:

- Consider how the current offerings could be improved, re-designed, or customized to better suit the customers’ needs.

- Review current manufacturing options, looking at what could be overhauled, perhaps mixing old and new processes to find optimal outputs.

- Look at the entire commercial ecosystem and assess the strategic implications around 3D printing, especially how it will be part of a company’s Industry 4.0 or IIoT strategy.

- Weigh-up where and when to make investments in 3D printing. Determine whether the risk of waiting is overshadowed by the risk of moving too soon to a new technology. This is ever more important when competitors have already begun to make moves.

The jury is still out as to whether 3D printing will completely replace existing manufacturing methods, but what is known is that the new technology is already having a dramatic effect on the way businesses operate today. Business leaders need to look at their entire operations to determine how 3D printing can be best used in their company and with their supply chains.

Mythos Group’s white paper, Post-COVID-19: Re-imagining A New Era of Work, contains more detail on this and other recommendations, and is available to download for free from https://bit.ly/MG-White Papers.